Your Trustful Inverter Supplier

The Yingwangxin Inverter is a high-performance device designed to convert direct current (DC) into alternating current (AC). Engineered with advanced technology, it ensures efficient and reliable conversion, providing stable power for a wide range of machinery and systems. The Yingwangxin Inverter is ideal for various applications in industries such as manufacturing, renewable energy, and more. Its robust design ensures durability and longevity, even in demanding industrial environments. Easy to install and operate, the Yingwangxin Inverter offers a user-friendly interface and comprehensive protection features, making it a safe and reliable choice for your power conversion needs. Coupled with our exceptional customer support, the Yingwangxin Inverter stands as a trusted solution for all your power conversion requirements.

Showing 49–60 of 93 results

-

Inverter

FR-A840-00038-2-60 1PCS NEW Original Mitsubishi Inverter FR-A840-00038-2-60

Read moreRated 0 out of 5 -

Inverter

FR-D720S-0.2K 1PCS New In Box MITSUBISHI Inverter Free Fast Shipping

Read moreRated 0 out of 5 -

Inverter

FR-D720S-0.4K-CHT NEW MITSUBISHI INVERTER PLC MODULE FR-D720S-0.4K-CHT

Read moreRated 0 out of 5 -

Inverter

FR-D720S-0.75K-CHT 1PCS NEW MITSUBISHI INVERTER PLC MODULE FR-D720S-0.75K-CHT

Read moreRated 0 out of 5 -

Inverter

FR-D720S-2.2K-CHT New Mitsubishi Frequency Converter FR-D720S-2.2K-CHT

Read moreRated 0 out of 5 -

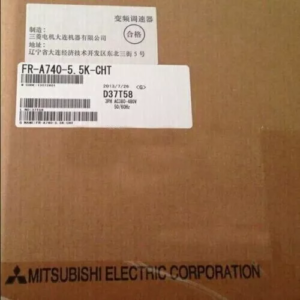

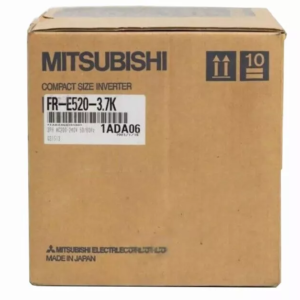

Inverter

FR-D740-050-NA New Sealed Mitsubishi Compact Size Inverter FR-D740-050-NA

Read moreRated 0 out of 5 -

Inverter

FR-D740-5.5K-CHT New Sealed Mitsubishi Compact Size Inverter FR-D740-5.5K-CHT

Read moreRated 0 out of 5

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Inverter

Variable-frequency Drive (VFD) is a power control equipment that uses Variable frequency technology and microelectronic technology to control AC motor by changing the working power frequency of motor.

The frequency converter is mainly composed of rectifier (AC to DC), filter, inverter (DC to AC), braking unit, driving unit, detection unit, micro processing unit, etc. Frequency converter depends on the internal IGBT off to adjust the output power supply voltage and frequency, according to the actual needs of the motor to provide its needed power supply voltage, so as to achieve the purpose of energy saving, speed regulation, in addition, the frequency converter has a lot of protection functions, such as over current, over voltage, overload protection and so on. With the continuous improvement of industrial automation, frequency converter has been widely used.

Features of Frequency Converter

It allows Programmable I/O. Programmable I/O is very useful for allowing digital servo drives to interact with each other or other elements in a system with simple high/low voltage signals assigned by the user.

Safe torque off is a safety feature provided by many digital servo drives to immediately power down the motor without powering down the servo drive.

It supports auxiliary feedback and dual loop control.

It allows high speed capture. High speed capture is the process of capturing motor position data within microseconds of being triggered, allowing very precise tracking of load position even at high speeds.

Characteristics of frequency converter (inverter)

Multiplex PWM mode control, output voltage waveform close to sine wave.

The multiplicity of rectifier circuit, pulse number, high power factor, small input harmonics.

Modular design, compact structure, easy maintenance, enhance the product interchangeability.

Direct high-voltage output without output transformer.

Very low dv/dt output without any form of filter.

Some use optical fiber communication technology, improve the anti-interference ability and reliability of products.

Power unit automatic side power circuit, can achieve fault non-stop function.

How Does the Frequency Converter Work?

The working principle of frequency converter is to control the power control equipment of AC motor by changing the working power frequency of motor by applying the principle of frequency conversion technology and microelectronics technology. The frequency converter used now mainly adopts AC-DC-AC mode, which first converts the power frequency AC power into DC power through the rectifier, and then converts the DC power into AC power which can be controlled by frequency and voltage to supply the motor.

What Are Applications of Frequency Converter?

Frequency converter is a kind of power regulation equipment, mainly used to adjust the speed and output power of AC motor. It is used in a wide range of scenarios, including industrial production, air conditioning systems, elevator systems, new energy fields, etc.

General frequency inverter

It refers to the high performance frequency inverter that can be used with an ordinary cage-type asynchronous motor, can adapt to various loads of different nature, and has a variety of optional functions.

High-frequency inverter

In ultra-precision machining and high-performance machinery, high-speed motors are often used. To meet the driving requirements of these high-speed motors, high-frequency inverters adopting the PAM (Pulse Amplitude Modulation) control mode have appeared, and the output frequency of the frequency inverter can reach 3kHz.

MOSFET frequency inverters

MOSFET frequency converters use metal-oxide-semiconductor field-effect transistors as the power-switching device.MOSFETs have low on-resistance and fast switching characteristics, which makes them suitable for some applications that require high-frequency switching. These frequency converters are typically used in low-power applications and high-frequency applications.

High-performance dedicated frequency inverter

High-performance dedicated inverter is mainly used in the system with higher requirements for motor control. Compared with general-purpose inverters, most of the high-performance dedicated inverters adopt vector control mode, and the driving object is usually the special motor specified by the inverter manufacturer.

IGBT frequency inverter

IGBT frequency inverters use insulated gate bipolar transistors (IGBTs) as power-switching devices. IGBTs have high voltage tolerance and high switching speeds, making inverters ideal for high-power applications. IGBT frequency converters can achieve efficient power conversion and are widely used in industrial drives and motor control.

Things to Consider:Choose Frequency Converter

When choosing a frequency converter, key considerations include: motor type, torque requirements, application diversity, load type, voltage, full load amps (FLA), installation environment, energy efficiency, desired output frequency, and the reputation of the manufacturer; ensuring the converter matches your specific power needs and control requirements while considering the type of load your motor will be driving.

#1 Motor type

Different frequency converters are designed for specific motor types, like induction motors or permanent magnet synchronous motors (PMSMs), so compatibility is crucial.

#2 Torque requirements

Select a converter capable of providing sufficient torque at the motor’s peak running speed, especially for applications with high starting torque needs.

#3 Load type

Analyze the type of load your motor will handle (constant torque, constant power, variable torque) to choose a converter with suitable characteristics.

#4 Voltage and Frequency

Ensure the converter’s input voltage and output frequency match your power supply and desired motor operation.

#5 Full Load Amps (FLA)

Match the converter’s current rating to the motor’s full load amps to avoid overloading.

#6 Application diversity

Consider the specific application, like pumps, conveyors, or machine tools, as different applications may require specialized features.

#7 Energy efficiency

Look for a converter with high efficiency to minimize energy consumption, especially in applications with variable speeds.

#8 Installation environment

Choose a converter suitable for the operating temperature, humidity, and other environmental conditions.

#9 Control features

Depending on your application, you may need advanced control features like PID control, vector control, or communication protocols.

#10 Manufacturer reputation

Select a reputable brand with reliable after-sales support and proven track record.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86 175 0301 5773

- +86 189 2656 9286

- info@yingwangxin.com