Your Trustful Industrial Soft Starter Supplier

Discover the power of advanced technology with Industrial Automation Products from Yingwangxin. As a leading automation products company, our product range includes drives, PLC modules, inverters, HMI’s, motors, control systems, power supply, circuit breaker and more, all designed to enhance operational efficiency. With products from leading brands like Siemens, Mitsubishi, Allen-Bradley,ABB and etc, we offer solutions that are reliable, high-quality, and tailored to your specific needs.

Showing all 4 results

-

Allen-Bradley

150-C9NBD New Allen-Bradley AB SMC-3 9A Smart Motor Controller

Read moreRated 0 out of 5 -

Allen-Bradley

150-F25NBD New Allen-Bradley AB SMC Flex Smart Motor Controller

Read moreRated 0 out of 5 -

Allen-Bradley

150-F361NBD New Allen-Bredley AB SMC Flex Smart Motor Controller

Read moreRated 0 out of 5

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Industrial Soft Starter

Features of Industrial Soft Starter

Industrial soft starters have many features that help protect motors and improve energy efficiency:

Smooth starting

Soft starters gradually increase the motor's speed to reduce mechanical and electrical stress.

Motor protection

Soft starters protect motors from electrical stress, overcurrent, undercurrent, and failure.

Energy efficiency

Soft starters automatically reduce the load when the motor reaches full speed.

Adjustable settings

Many soft starters have adjustable settings for start and stop times, current limits, and more.

Reduced risk of power surges

Soft starters gradually increase voltage to the motor instead of throwing all the power into the circuits at once.

Extended equipment life

Soft starters reduce wear and tear on mechanical components, which can help extend the life of the equipment.

Improved installation efficiency

Some soft starters are compact and have built-in features that can reduce installation time and panel size.

Increased application productivity

Soft starters can reduce the number of stops in production by allowing for features like torque control and pump cleaning.

Conclusion

Soft starters can be mechanical, electrical, or a combination of both. Mechanical soft starters use clutches or couplings to transmit torque.

How Does the Industrial Soft Starter Work?

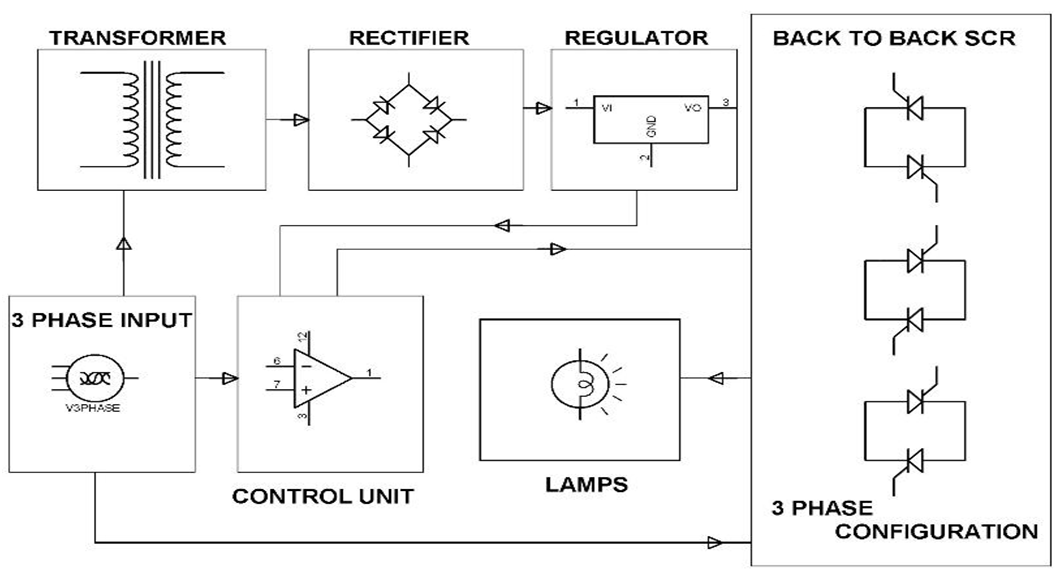

An industrial soft starter works by gradually increasing the voltage supplied to an electric motor during startup, effectively limiting the initial inrush current and providing a smooth acceleration, thus reducing mechanical stress on the motor and connected machinery; this is typically achieved using solid-state devices like thyristors (silicon controlled rectifiers) to control the voltage applied to the motor phases, allowing for a controlled ramp-up to full operating speed.

What Are Applications of Industrial Soft Starter?

- Conveyors: A sudden start can cause problems with conveyor belts.

- Pumps: There is a risk of power surges in pump applications.

- Fans and similar systems: Systems with belt drives can have similar problems to conveyor belts.

- Electrical helicopters: A sudden, jerky start could be disastrous for a helicopter.

- Manufacturing facilities: Soft starters are especially useful for motors heavily utilized in manufacturing facilities.

- HVAC systems: Soft starters are useful for motors in HVAC systems.

- Water treatment plants: Soft starters are useful for motors in water treatment plants

There are many types of industrial soft starters, including:

Primary resistor

A simple unit with a resistor for each phase of current that resists the current flow when the motor starts. This type of soft starter is ideal for motors that need limited torque to prevent damage to machinery.

Autotransformer

Uses taps on transformer windings to control the power input to the motor. This type of soft starter can supply more current to the motor than other soft starters, while keeping voltage low.

Part-winding

Divides the motor windings into two or more separate sets. At startup, only one set of windings is allowed power. The other sets are only released when the motor gains speed. This type of soft starter is ideal for motors that supply moving centrifugal force, like those found in pumps, fans, and blowers.

Wye-Delta

A common reduced voltage starter used in large horsepower and three-phase induction motors.

Solid state

Uses silicon-controlled rectifiers (SCRs) to replace mechanical components with electrical ones. This type of soft starter is often used in industrial applications, HVAC systems, processing equipment, elevators, and mining applications.

Cybersecurity soft starters

Designed to protect against casual or intentional interference or attacks. These soft starters include features such as user account management, threat intelligence, and secure boot.

Different type of Industrial Soft Starters

Conclusion

Soft starters can improve efficiency, reduce overheating, and increase equipment lifespan.

Things to Consider When Choosing Industrial Soft Starter

When selecting an industrial soft starter, key considerations include: motor size and type, application requirements, voltage and current needs, number of starts per hour, desired acceleration profile, heat dissipation capabilities, and whether the application demands features like overload protection or communication capabilities; essentially, matching the soft starter’s capacity to the motor’s starting current and the specific demands of the application.

#1 Motor size and power

The motor’s horsepower or kW rating directly impacts the size of the soft starter needed to handle its starting current.

#2 Motor type

Different motor types (induction, permanent magnet) may require specific soft starter configurations due to their unique start-up characteristics.

#3 Application needs

Consider the application’s starting requirements, like whether it needs a smooth start, rapid acceleration, or frequent starts and stops.

#4 Voltage and current rating

Ensure the soft starter is compatible with the motor’s voltage and full load current.

#5 Start-up torque requirements

If the application demands full torque at start, choose a soft starter designed for high starting torque.

#6 Number of starts per hour

Applications with frequent motor starts may need a soft starter with higher ampacity to handle heat generation from repeated starts.

#7 Acceleration and deceleration control

Check if the soft starter offers adjustable start and stop profiles to suit the application’s needs.

#8 Overload protection

Whether the soft starter includes built-in overload protection features to safeguard the motor.

#9 Environmental considerations

Check if the soft starter is suitable for the operating temperature and humidity of the environment.

#10 Communication capabilities

If integration with a control system is required, consider soft starters with communication protocols like Modbus.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86 175 0301 5773

- +86 189 2656 9286

- info@yingwangxin.com