Your Trustful Servo Drive Supplier

Discover the power of advanced technology with Industrial Automation Products from Yingwangxin. As a leading automation products company, our product range includes drives, PLC modules, inverters, HMI’s, motors, control systems, power supply, circuit breaker and more, all designed to enhance operational efficiency. With products from leading brands like Siemens, Mitsubishi, Allen-Bradley,ABB and etc, we offer solutions that are reliable, high-quality, and tailored to your specific needs.

Showing all 11 results

-

Allen-Bradley

2097-V32PR0-LM New Allen-Bradley AB Kinetix 350 400W Servo Drive

Read moreRated 0 out of 5 -

Allen-Bradley

2097-V33PR5-LM New Allen-Bradley AB Kinetix 350 2.0kW Servo Drive

Read moreRated 0 out of 5 -

Allen-Bradley

2097-V34PR3-LM New Allen-Bredley AB Kinetix 350 1.0kW Servo Drive

Read moreRated 0 out of 5 -

Allen-Bradley

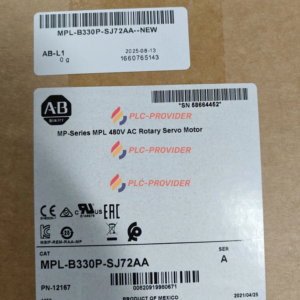

New Sealed MPL-B330P-SJ72AA Allen-Bradley MP-Series MPL 480V AC Rotary Servo Motor

Read moreRated 0 out of 5

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Industrial Servo Drive

Features of Industrial Servo Drive

Closed-loop control

Continuously monitors the motor's actual position using an encoder to compare it to the desired position, allowing for automatic adjustments to maintain accuracy.

High precision positioning

Can precisely control the motor's position with minimal overshoot or error.

Fast response time

Ability to quickly accelerate and decelerate, enabling rapid changes in motion.

Wide speed range

Operates over a broad range of speeds, from very slow to very fast.

High torque capability

Delivers significant torque to drive heavy loads.

Programmable motion profiles

Can be programmed to execute complex motion sequences like S-curve acceleration and deceleration

Multiple feedback options

Supports different types of encoders (e.g., incremental, absolute) for various applications

Multi-axis control

Capability to control multiple motors simultaneously for coordinated motion

Digital communication interfaces

Connects to a control system using standard communication protocols like Ethernet, Profibus, or CANbus

Safety features

Includes functions like safe torque off (STO) to prevent unexpected motor movement in hazardous situations

Parameter tuning

Allows for adjustments to motor performance based on application requirements (e.g., gain, damping)

How Does the Industrial Servo Drive?

An industrial servo drive receives a command signal from a controller, amplifies it, and then precisely controls the position, speed, and torque of a connected servo motor by adjusting the power supplied to it, utilizing feedback from a position sensor (encoder) to ensure the motor reaches the desired position with high accuracy; essentially acting as a “brain” that translates control commands into precise motor movements.

What Are Applications of Industrial Servo Drive?

Servo drives are used for many applications. As they are built into wider devices they are found in many different industries.

Some application areas for servo drives include;

- Aerospace

- Marine

- Aviation

- Satellite Communication

- Laboratory Automation

- Arctic Drilling

- Ground Mobile

- Extreme Outdoor Operation

Linear servo motors

These motors are designed for direct drive applications and offer high precision in linear motion. They are simpler and more reliable than other types of motors because they don't require mechanical transmission elements.

Stepper motors

These motors make discrete steps, which makes them well-suited for low-speed, open-loop positioning applications. They are a cost-effective solution.

Rotary servo motors

These motors work by turning something in circles. They are often used in food and beverage processing equipment, such as electric food mixers.

AC servo motors

These motors provide excellent control over a wide range of speeds. They are equipped with sophisticated feedback mechanisms, such as encoders or resolvers.

DC motors

These motors are commonly used to power the wheels on electric vehicles, but they can also be used for industrial applications such as food processing, machine tools, and material handling.

Brushed servo motors

These motors feature a rotor with a commutator and brushes that come into contact with the rotor windings to create a magnetic field.

Brushless DC motors

These motors are a good choice for applications where the motor may not be easily accessible for maintenance or higher efficiency is desired.

Different type of Industrial Servo Drive

There are many types of industrial servo drives, including:

Things to Consider When Choosing Industrial Servo Drive

When selecting an industrial servo drive, key factors to consider include: power rating, voltage requirements, current rating, speed rating, efficiency, application needs (torque, acceleration, precision), feedback type, environmental conditions, compatibility with the chosen servo motor, and the level of control features offered by the drive; ensuring the drive can handle the specific demands of your application while providing the necessary performance and reliability.

#1 Power Requirements

- Horsepower/kW rating: Match the drive’s power rating to the maximum power needed by your application.

- Voltage: Select a drive compatible with your power supply voltage.

- Current Rating: Ensure the drive can deliver sufficient current for the motor under load.

#2 Performance Specifications

- Speed: Consider the maximum operating speed required for your application.

- Torque: Choose a drive that can provide the necessary torque to handle your load.

- Acceleration/Deceleration: Select a drive with appropriate acceleration and deceleration capabilities for your application.

- Position Accuracy: Consider the level of precision needed for your application.

#3 Feedback Mechanism

- Encoder type: Choose the encoder feedback that best suits your application (e.g., incremental, absolute).

- Resolution: Select a resolution that provides the desired level of position accuracy.

#4 Control Features

- Motion profiles: Consider if you need advanced motion profiles like S-curve acceleration.

- PID control: Check if the drive has built-in PID control for fine-tuning performance.

- Communication protocols: Ensure the drive is compatible with your control system’s communication protocol.

#5 Environmental Factors

- Operating temperature: Select a drive suitable for the expected operating temperature range.

- Vibration resistance: Consider if vibration resistance is a requirement for your application.

- Ingress protection (IP rating): Choose a drive with an appropriate IP rating for the level of environmental protection needed.

#6 Compatibility with Servo Motor

- Motor type: Ensure the drive is compatible with the chosen servo motor (e.g., AC, DC, brushless).

- Motor parameters: Match the drive parameters (voltage, current, etc.) to the motor specifications.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86 175 0301 5773

- +86 189 2656 9286

- info@yingwangxin.com