Your Trustful HMI Touch Screen Supplier

Discover the power of advanced technology with Industrial Automation Products from Yingwangxin. As a leading automation products company, our product range includes drives, PLC modules, inverters, HMI’s, motors, control systems, power supply, circuit breaker and more, all designed to enhance operational efficiency. With products from leading brands like Siemens, Mitsubishi, Allen-Bradley,ABB and etc, we offer solutions that are reliable, high-quality, and tailored to your specific needs.

Showing 1–12 of 74 results

-

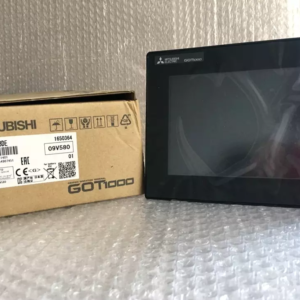

HMI

1PC New Mitsubishi GT1020-LBD-C Touch Screen Expedited Shipping GT1020LBDC

Read moreRated 0 out of 5 -

HMI

1PC New Omron NS5-TQ11B-V2 HMI Touch Screen Expedited Shipping NS5TQ11BV2

Read moreRated 0 out of 5 -

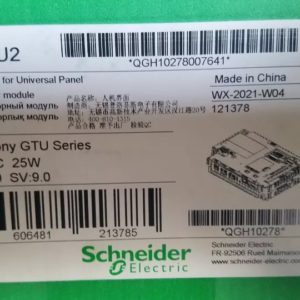

HMI

1PC New Schneider HMIG5U2 Touch Screen PLC Module In Box Expedited Shipping

Read moreRated 0 out of 5 -

HMI

1PC Omron NB10W-TW01B Touch Screen New In Box Expedited Shipping NB10WTW01B

Read moreRated 0 out of 5

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About HMI Touch Screen

The HMI Touch Screen is an innovative interface designed to simplify the control and monitoring of automated systems. HMI touch screen panel combines advanced technology with user-friendly design, allowing operators to interact with the system in a more intuitive and efficient manner. The HMI Touch Panel provides clear visualizations and real-time data, enabling quick decision-making and improved productivity. Its robust construction ensures durability, even in the most demanding industrial environments. Easy to install and operate, the HMI display touch screen is an essential tool for modern industrial settings, enhancing the interaction between humans and machines. With our exceptional customer support, the wireless HMI touch screen is your reliable partner for a seamless and efficient automation experience.

Features of Industrial Touch Screen HMI

Industrial touch screen HMI has a variety of choices and competitive prices, reliable, efficient, high-quality products, the best features, animation editing diverse, high-resolution graphics, using C language programming, panel 7″ or more optional stainless steel front frame, IP 66K protection level, can be used in harsh environments. Some typical dimensions as follows:

10 Inch HMI Touch Screen

7 Inch HMI Touch Screen

HMI 4.3 inch

HMI 4 inch

Working Principle of HMI Touch Screen Panel

Man-machine interface products are composed of hardware and software parts, the hardware part includes processor, display unit, input unit, communication interface, data storage unit, etc., in which the performance of the processor determines the performance of HMI products and is the core unit of HMI. HMI software is generally divided into two parts, namely the system software running in the HMI hardware and the screen configuration software running under the Windows operating system of the PC.

Applications of HMI Display Panel

HMI display screens are commonly used in manufacturing environments to control and monitor production processes.They can be used to present process data to operators, allowing them to enter commands and setpoints, as well as display alarms and other important information. HMIs are also used in power plants to monitor and control processes such as boiler operation, turbine control, and power generation and distribution.HMIs are used in water and wastewater treatment plants to control and monitor processes such as pumping, treatment and distribution.HMIs are used in oil and gas production and refining to control and monitor processes such as drilling, pumping and refining.

Different Type of HMI Touch Screen

Standard HMIs

The most common HMI screens. They are versatile and can connect to many different Programmable Logic Controllers (PLCs). These kinds of screens are typically straightforward and user-friendly, making them ideal for most industrial applications including manufacturing, energy, food and beverage, etc.

Web Panel HMIs

These screens come with HTML 5 built-in for web server applications. This means that operators can access and control them through web browsers. This makes remote monitoring and control easy. If your application requires internet connectivity and remote access, Web Panel HMIs are the way to go.

Outdoor Readable HMIs

Outdoor Readable HMI screens are designed to combat glare and touch sensitivities caused by sunlight. They are built to withstand adverse outdoor conditions and environments, making them perfect for outdoor installations. They are commonly used in the transportation and energy sectors.

Maritime HMIs

Maritime HMI screens are very unique and meet the requirements for shipbuilding. They are built to withstand hard marine conditions and comply with maritime standards. Maritime HMI screens, as the name suggests, are ideal for ships, oil rigs, and other maritime environments.

Headless HMIs

Headless HMIs are built without a touch screen. Instead, they are controlled over a network connection and accessed from a PC, smartphone, or separate touch display. They are also ideal for remote control and monitoring, and within applications where space may be limited or where a physical display isn’t necessary.

Other Components of an HMI

HMIs don’t only include the main screen types, there are other components that can help increase their functionality.

The Overview Screen

Overview screens, or panel viewers, are used to view SCADA (Supervisory Control and Data Acquisition) and MES (Manufacturing Execution Systems). They allow you to handle and observe multiple machines or processes from one station. These screens are ideal for increasing operational efficiency by managing and observing multiple machines or processes from a single location. They make it easier to operate and monitor large-scale industrial processes.

The Data Dashboard Screen

Data dashboard screens display information related to machine performance. They provide feedback and insights into how machines are operating, enable recipe programming, and alert users to warning alarms. These screens are used for monitoring performance metrics and visualizing production data. They are perfect for creating quick summaries of overall production reports and ensuring everything runs smoothly.

Push Button Panels

Push button panels have been largely replaced by touchscreen interfaces. These touchscreens allow centralized operation control from a single panel, eliminating the need for numerous physical push buttons. These panels simplify machine operation, allowing users to perform various functions like start-stop, homing, navigating through different screens, and resetting. They reduce the need for physical buttons and make machine operation much more straightforward.

Things to Consider:Choose an HMI Screen

When choosing an HMI screen for your specific application, several factors should be considered to ensure you pick the right one:

#1 Driver Support

Ensure the HMI supports the drivers needed for your equipment

#2 Communication Ports

Check the availability and type of communication ports (e.g., Ethernet, USB) required for your application.

#3 Display Properties

Consider the size and resolution of the display. Larger screens may be necessary for complex operations, while smaller ones may suffice for simpler tasks

#4 HMI Programming Software

Ensure the HMI is compatible with the programming software you use.

#5 Performance

Look at the CPU and RAM specifications to ensure the HMI can handle the required tasks without lag.

#6 Remote Access

Determine if remote access capabilities are necessary for your operations.

#7 Security

Evaluate security features such as user accounts and IP protection to safeguard your operations.

#8 Certification and Compliance

Make sure the HMI meets the necessary certifications and compliance standards for your industry.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86 175 0301 5773

- +86 189 2656 9286

- info@yingwangxin.com