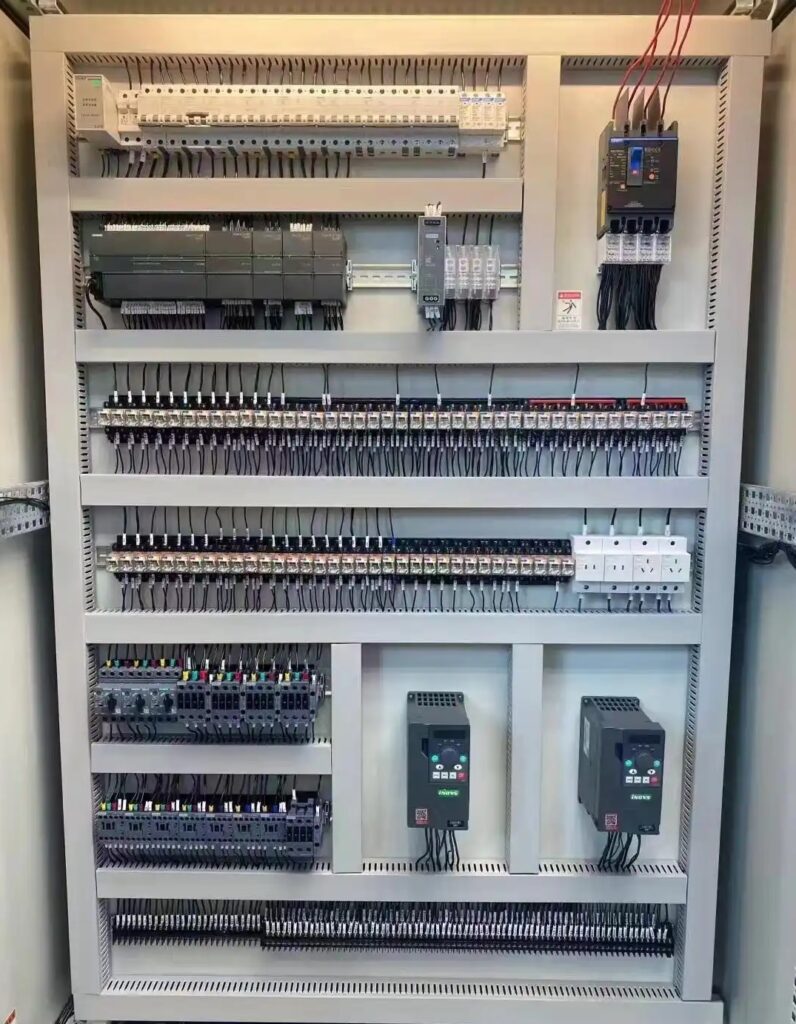

In sewage treatment, PLC (Programmable Logic Controller) modules play a key role. Different types of modules have different functions. The following is a detailed introduction to the commonly used PLC modules in sewage treatment:

Digital Input (DI) Module

Function: Used to collect various switch signals in the sewage treatment system. These signals can reflect the operating status of the equipment, such as the start and stop status of water pumps and fans, the opening and closing status of valves, etc.

Working Principle: The switch signal of the external device is converted into a digital signal that can be recognized by the PLC through the input circuit. Generally, photoelectric isolation technology is used to improve the anti-interference ability.

Application scenario: Monitor the operating status of the screen machine. When the screen machine is operating normally, the DI module receives its corresponding switch signal and transmits it to the PLC. The PLC performs subsequent processing according to the preset program; detects the opening and closing position of the electric valve, and feeds back the valve opening or closing signal to the PLC.

Digital Output (DO) Module

Function: Mainly used to control the start and stop of sewage treatment equipment, the opening and closing of valves, etc. It converts the control instructions of the PLC into switch signal output to drive the external load.

Working principle: According to the logical operation results of the PLC internal program, the output circuit of the output module generates corresponding switching actions to drive actuators such as relays and contactors.

Application scenario: Control the start and stop of the water pump. When the water level in the pool reaches the set value, the PLC sends a signal through the DO module to start or stop the water pump; control the opening and closing of the electric valve to adjust the water flow.

Analog input (AI) module

Function: Used to collect various analog signals in the sewage treatment process, such as liquid level, flow, pressure, temperature, pH value, dissolved oxygen and other parameters. These parameters are continuously changing and need to be converted into digital signals that can be processed by the PLC through the AI module.

Working principle: A/D (analog/digital) converters are usually used to convert analog signals into digital signals. Common input signal types include current signals (such as 4-20mA) and voltage signals (such as 0-10V).

Application scenario: Collect the signal of the liquid level sensor in the sewage pool to monitor the water level in real time; obtain the flow signal of the flow meter to control the flow of water inlet and outlet.

Analog output (AO) module

Function: Convert the digital signal processed by PLC into analog signal output, which is used to control some equipment that requires continuous adjustment, such as frequency converter, regulating valve, etc., to achieve precise control of parameters such as flow, pressure, and temperature.

Working principle: Convert the digital signal into the corresponding analog signal through the D/A (digital/analog) converter. The output signal type is generally a current signal (such as 4-20mA) or a voltage signal (such as 0-10V).

Application scenario: Control the output frequency of the frequency converter to adjust the speed of the water pump or fan to achieve precise control of flow or pressure; adjust the opening of the regulating valve to control the dosage of the agent.

Communication module

Function: To realize the communication connection between PLC and other devices, such as data transmission and exchange with the host computer monitoring system, other PLCs, intelligent instruments, etc., to realize remote monitoring, data sharing and collaborative control.

Working principle: Different communication modules use different communication protocols and interface standards. Common communication protocols include Modbus, Profibus, Ethernet, etc., and interface types include RS485, RS232, Ethernet interface, etc.

Application scenario: To communicate the PLC at the sewage treatment site with the host computer of the remote monitoring center, upload the equipment operation status and process parameters in real time, and receive the control instructions of the host computer at the same time; to realize data exchange between multiple PLCs and coordinate the operation of different processing units.

Special function module

High-speed counting module: used to count high-speed pulse signals, which can be used to measure the speed and flow pulse of the equipment in sewage treatment. For example, by counting the pulse signal output by the electromagnetic flowmeter, the flow of sewage can be accurately measured.

PID control module: It is specially designed to implement the PID (proportional-integral-differential) control algorithm, which can accurately control the liquid level, temperature, pressure and other parameters in a closed loop. For example, when adjusting the dissolved oxygen content in the aeration tank, the PID control module automatically adjusts the fan air volume according to the deviation between the actual measured value and the set value.