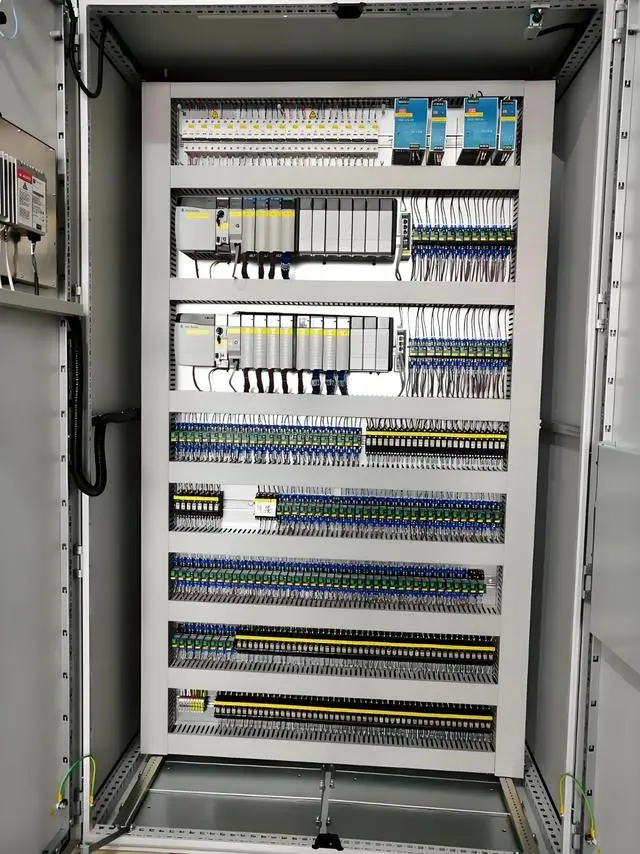

Here are some quick ways to find the fault point of a PLC control cabinet:

1. Observation and inquiry

- Observe the indicator lights:Check the status of various indicator lights on the PLC control cabinet. For example, the power indicator light, the operation indicator light, the fault indicator light, etc. If there is an abnormal indicator light, you can preliminarily judge that there may be a problem with the relevant part.

Observe the indicator lights of the input and output modules to understand whether the input signal is received normally and whether the output signal is sent correctly.

- Check the display information:If the PLC has a display screen, check the error code, alarm information, etc. displayed on it. This information can provide specific clues about the fault.

- Ask the operator:Understand the situation when the fault occurs, such as what operation the device is performing, whether there are abnormal sounds or phenomena, etc. This helps to determine the possible scope of the fault.

2. Hardware inspection

- Check the power supply:Confirm whether the power supply of the control cabinet is normal. Measure whether the input voltage is within the specified range, and check whether the power switch, fuse, etc. are intact.

Check the power supply module of the PLC and other equipment to see if there is an abnormal output voltage or the indicator light is not on.

- Check the wiring:Check whether all the wiring in the control cabinet is firm, loose, falling off or short-circuited. Pay special attention to the input and output signal lines, communication lines, etc.

Check whether the connection on the terminal block is correct and whether there is any wrong connection.

- Check the module:For the input and output modules, communication modules, etc. of the PLC, check whether their indicator lights are normal. You can try to re-plug the module to see if the problem can be solved.

If there is a spare module, you can perform a replacement test to determine whether the fault is in the module itself.

- Check the sensors and actuators:Check whether the sensors and actuators connected to the PLC are working properly. For example, use a multimeter to measure whether the output signal of the sensor is normal and check whether the actuator can operate correctly.

3. Software Diagnosis

- Use programming software:Connect to PLC through programming software to check the program’s running status, variable values, etc. Check whether there are program errors, logic errors or data anomalies.

Use the diagnostic function of the programming software to check the PLC’s error log, alarm information, etc. to determine the specific location of the fault.

- Online monitoring:Carry out online monitoring, observe the state changes of each input and output point in the program, compare with the actual operation of the device, and find out the inconsistencies.

Certain input and output points can be forced to test the logic of the program and the response of the device.

4. Segmented troubleshooting

- Divide the area:Divide the system of the PLC control cabinet into several areas, such as the input part, control part, output part, etc. Check each area one by one to narrow the scope of the fault.

- Isolate equipment:If possible, isolate some equipment from the system to observe whether the fault still exists. This can determine whether the fault is in the isolated equipment or in other parts.

5. With the help of tools

- Multimeter:Use a multimeter to measure parameters such as voltage, current, resistance, etc. to check whether the circuit is normal. For example, measure power supply voltage, sensor output signal, actuator coil resistance, etc.

- Oscilloscope:For some complex signal problems, you can use an oscilloscope to observe the waveform of the signal and determine whether the signal is normal. For example, check communication signals, pulse signals, etc.

- Fault diagnosis instrument:Some professional fault diagnosis instruments can quickly detect faults in PLC control cabinets and provide detailed fault information and solutions.